A Guide to Product Cost: Understanding What Makes the Cost of Product

This retained earnings leads to improved profitability and a stronger competitive position in the market. Used when identical items are produced in batches rather than individually. The total batch cost is divided by the number of units to get per-unit cost. Common in garment, medicine, and food industries, it ensures cost consistency for similar production runs. That’s the cost of making one more unit of a given good, and it can help you make supply and sales pricing decisions. That’s because as you make more products, the per-unit product cost can come down.

- A major electronic firm systematically tracks direct material cost by using automated inventory systems.

- These advanced analytical approaches transform total cost management from simple expense control to strategic optimization of the entire business system.

- It includes costs that can be directly attributed to a specific product as well as indirect costs.

- Understanding the cost of production is more than just a financial necessity—it’s a strategic imperative.

- To compute production cost accurately, first gather comprehensive data on direct materials, direct labor, and manufacturing overhead.

How to Choose the Best Fulfillment Provider for a Scaling Ecommerce Business

Therefore, the production cost of the company add up to $1.39 million for the period. We will again calculate the manufacturing cost first to simplify the formula. For example, a small bakery might include bakers and decorators as direct labor, but count the delivery driver and store manager as overhead. In the short run, some of the factors are fixed, while other factors are variable.

- Reducing production costs involves analysing and controlling the different types of costs to optimise efficiency, pricing strategies, and overall financial performance.

- Additionally, developing a responsive production plan that can quickly adjust to shifts in demand ensures efficient resource allocation.

- It is because, at all output levels (even at zero level), TFC remains the same.

- While pure variable costs change in exact proportion to activity levels, many real-world expenses combine fixed and variable elements.

- However, it is usually preferable to compute this cost per unit because it might aid in determining the right finished product sales price.

Types of product costs

Automated systems enable real-time monitoring and data collection, providing valuable insights for strategic decision-making and process optimization. Additionally, having the expertise in system handling ensures effective automation of tasks, thereby streamlining service and repair processes when needed. By automating routine tasks, businesses can allocate human resources to more complex and creative total product cost formula activities, fostering innovation and improving workforce productivity. Variable costs, on the other hand, fluctuate depending on the quantity of goods produced.

- Direct labor costs include the wages and benefits paid to employees who are directly involved in the production of goods.

- Once you have calculated your total product cost, evaluate whether your current pricing strategy is sustainable and profitable.

- Moreover, monitoring the cost per unit over time provides valuable insights into trends and allows for a real-time analysis of expenses and revenue.

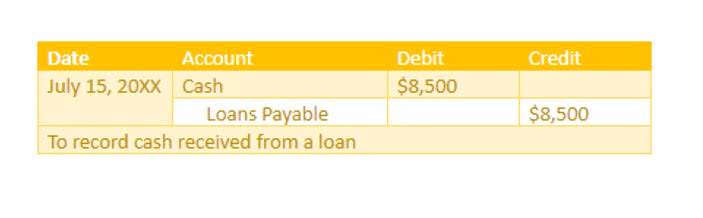

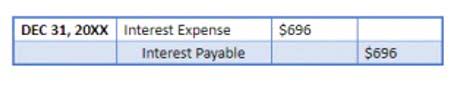

- These formulas enable accountants to calculate operational parameters and assess the profitability of specific products.

- Managing these costs involves ensuring productivity and efficiency among workers, often achieved through training and optimizing work processes.

Editorial Process

To calculate total manufacturing costs, you must first sum up all the direct materials used in production. Total cost analysis provides business leaders with powerful insights that directly inform critical financial decisions affecting both short-term performance and long-term strategic direction. Conversely, operations with predominantly variable cost structures might focus on efficiency improvements and waste reduction to enhance profitability at any production level. These strategic insights enable businesses to align their improvement initiatives with their specific cost structure for maximum financial impact. Fixed costs https://somas.ma/insurance-receivables-a-key-element-of-other/ are expenses that do not change with the level of output, such as rent and salaries.

Accurate tracking of direct labor is crucial, as it influences product pricing and overall profitability. This simple formula shows how to find total manufacturing costs accurately and helps businesses understand their production expenses. By using this method, you can easily calculate total manufacturing costs for any production process. Dynamic pricing strategies have emerged as increasingly powerful tools that continuously adjust prices based on fluctuating costs, market conditions, competitor actions, and customer behavior.

Turn Cost Data Into Profit: Why These Formulas Matter

- These costs are capitalised and reported on the balance sheet as inventory until the goods are sold, at which point they are expensed as Cost of Goods Sold (COGS) on the income statement.

- Meanwhile, optimizing logistics operations decreases variable costs such as labor and material costs.

- The management of Raymond’s has estimated its costs to direct material, direct labor, and factory overhead costs.

- Discover how greenhouse growers software can boost yields, cut costs, and drive sustainability.

- This forward-looking approach transforms total cost analysis from a retrospective accounting exercise into a powerful strategic planning tool.

- Implementing smart technologies, such as automated controls and energy-efficient machinery, can result in significant reductions in power consumption.

Jami has collaborated with clients large and small in the technology, financial, and post-secondary fields. Marginal costs will help find the ideal and most optimum level of production for your product or service. Effective inventory management techniques such as proper demand forecasting, Just-In-Time (JIT) inventory management, and RFID technology can all help lower the cost per unit.